CONTROLLING THE RIDE

We take a look at the various ways of attaching wheels to your RV

WORDS BY GRANT HANAH, PHOTOGRAPHY BY CARAVAN AND MOTORHOME

In this article we provide an insight into the variety of different suspension setups that are on the market today and explain how they differ from one another.

THE PURPOSE OF SUSPENSION

If the roads we towed on were perfectly flat, then our RVs wouldn’t need suspension. But since they vary from fresh bitumen to potholed horror stretches, our vans need to be able to cope in all conditions.

Without suspension, those bumps would cause the after-shock to go right through the frame of our van. The wheels would lose contact with the road, then skid back again, making towing not just difficult but downright dangerous. Suspension, by keeping the wheels and tyres of our van in contact with the ground, is designed to counteract these forces of gravity, propulsion and inertia when we accelerate or brake heavily.

THREE THINGS SUSPENSION SHOULD DO

1. Contact. Keep the tyres of the RV in contact with the road surface.

2. Handling. Keep the RV from tipping or rolling into a corner as it absorbs the centrifugal forces.

3. Comfort. Keep the contents of the RV isolated from the bumps on the road.

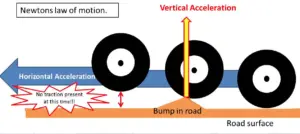

NEWTON’S LAW OF MOTION

Without being too technical, Newton’s Law of motion suggests that all forces have both magnitude and direction. Simply put, a deviation in the road surface causes the wheel to move up and down perpendicular to the road. The magnitude naturally depends on whether the wheel is hitting a large or small bump. Either way the wheel will experience a vertical acceleration as it passes over the deviation.

Suspension absorbs the deviation and reduces the rate of vertical acceleration. Understanding this concept gives you a better appreciation why you need suspension.

SO MANY CHOICES

Just as there are different styles of caravans in the market, there are also different suspensions and setups. Not all suspension systems are the same, nor do they work or cost the same to manufacture. Some are lowmaintenance while others need regular inspections and servicing. Some are designed for the black top while others are designed for off-road dirt tracks.

To help allay the confusion let’s take a closer look at the more popular types to see how they work.

SUSPENSION TYPES

Let’s look at some of the different suspension options on offer.

LEAF SPRINGS AND AXLE SETUPS

This is the simplest set up of the lot. Leaf springs come as single leaf or in packs and are clamped together. The longer the spring, the greater the flex. The greater the number of leaves, the more load it can carry.

SLIPPER SPRINGS

This is the least expensive type of spring as it is fixed only at one end. At the opposite end, the spring is flattened out slightly. This results in a sliding contact with the chassis frame. Offered on many smaller RVs, this works fine provided suitable ratings of springs and axles are selected.

EYE TO EYE SPRING

Using a form of bush at each end, the eye-to-eye spring can flex more freely and is quieter and smoother in operation. To tune a leaf spring suspension, it’s necessary for engineers to determine the length of the spring, its thickness and the width of each leaf then calculate the number of leaves. Leaf spring manufacturers provide rating charts to guide buyers in the right selection.

TORQUE – ARM SUSPENSION

Consists of an outer square tube into which a splined shaft surrounded by a rubber/urethane compound is introduced under high pressure. The stub is welded offset to the splined shaft which provides the action for the tube to twist against the rubber compound under load. They work well provided they’re not overloaded, but replacing of the rubber can be done only by the manufacturer due to the unique process.

TANDEM ROCKER SUSPENSIONS

These are also known as load sharing (not independent) and are designed to distribute the weight across all four wheels. When compared to fully independent, they are a lot cheaper and are the most common tandem suspension setup. They do require regular maintenance due to bush wear.

TANDEM ROCKER – ROLLER SUSPENSIONS

This is similar to Rocker suspension although there is a big loop at the end of each spring where a roller runs. The loops allow for small axle movement, while bigger axle movement rocks on the main pivot arm. This type has a longer service life and is less prone to spring breakages.

INDEPENDENT SUSPENSIONS

These types of suspensions are popular and are built specifically for off road use. The design uses a pivoted leading edge fitted up with a stub axle wheel bearing assembly. The load is taken by a trailing arm arrangement in conjunction with other components such as coils or leaf springs, and some now use an airbag. Each wheel is able to move independently of any other wheel.